In 2011, a mid-sized manufacturing company in Vishakhapatnam, Andhra Pradesh was facing a crisis. Despite having over 1,800 workers and 250 managers, they were running ₹65 Cr in annual losses, and failing to supply critical parts to global tractor manufacturers.

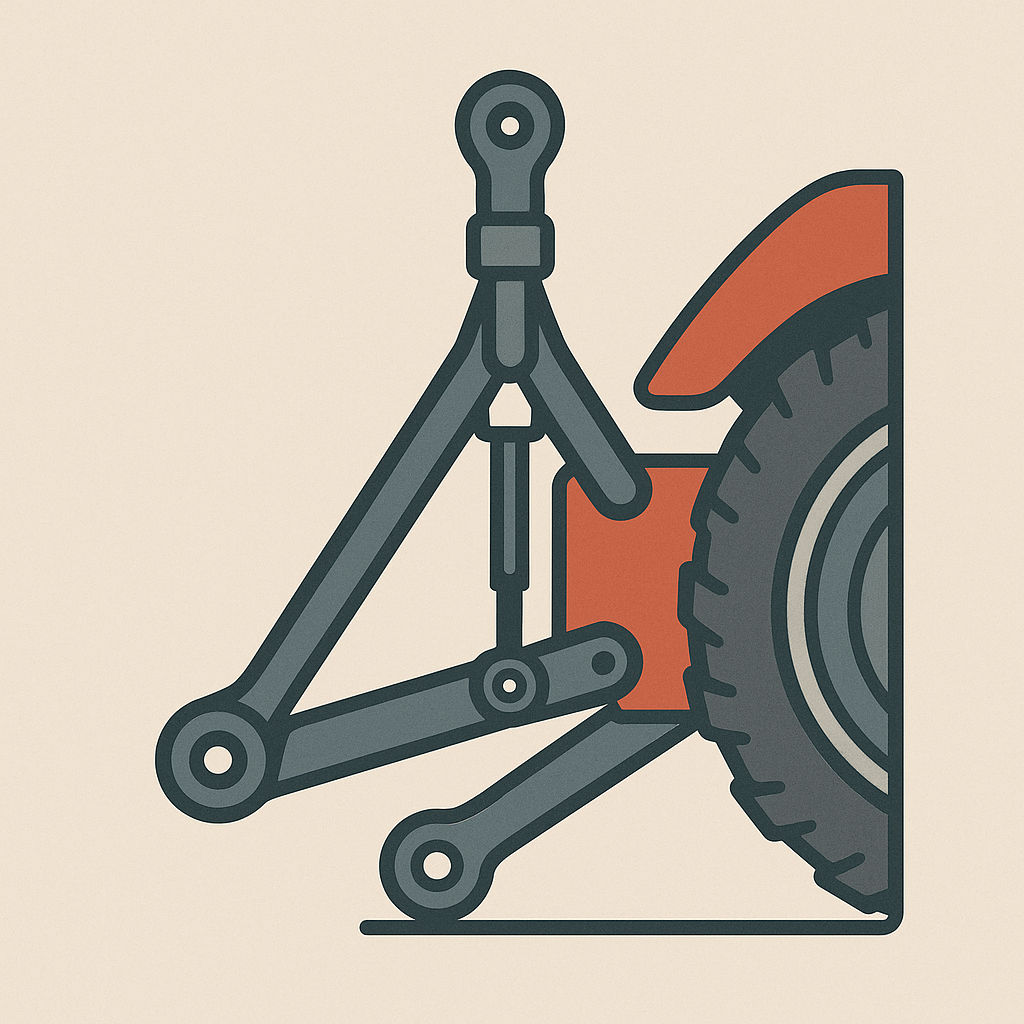

They produced 10,000 precision-machined and three-point linkage parts, but faced rampant bottlenecks, shortages, and missed deliveries.

I stepped in with a 90-day throughput improvement program using the Theory of Constraints. We:

- Identified and eliminated multiple bottlenecks across their machining and assembly operations.

- Restructured workflows without additional headcount or capex.

- Reduced manpower from 1,800 to 1,100 and management from 250 to 110, increasing efficiency.

- Tripled their output—from ₹4 Cr to ₹15 Cr/month in under 3 months.

- Brought the company to break-even and then sustainable profitability.

Today, this company is a market leader and has a stable global supply chain footprint.

If you’re a manufacturing business struggling with low throughput, late deliveries, or mounting operational inefficiencies, I can help you achieve similar results — in just 90 days.

Rajnish Devraj Sharda RDS

MSME Growth Strategist